Services

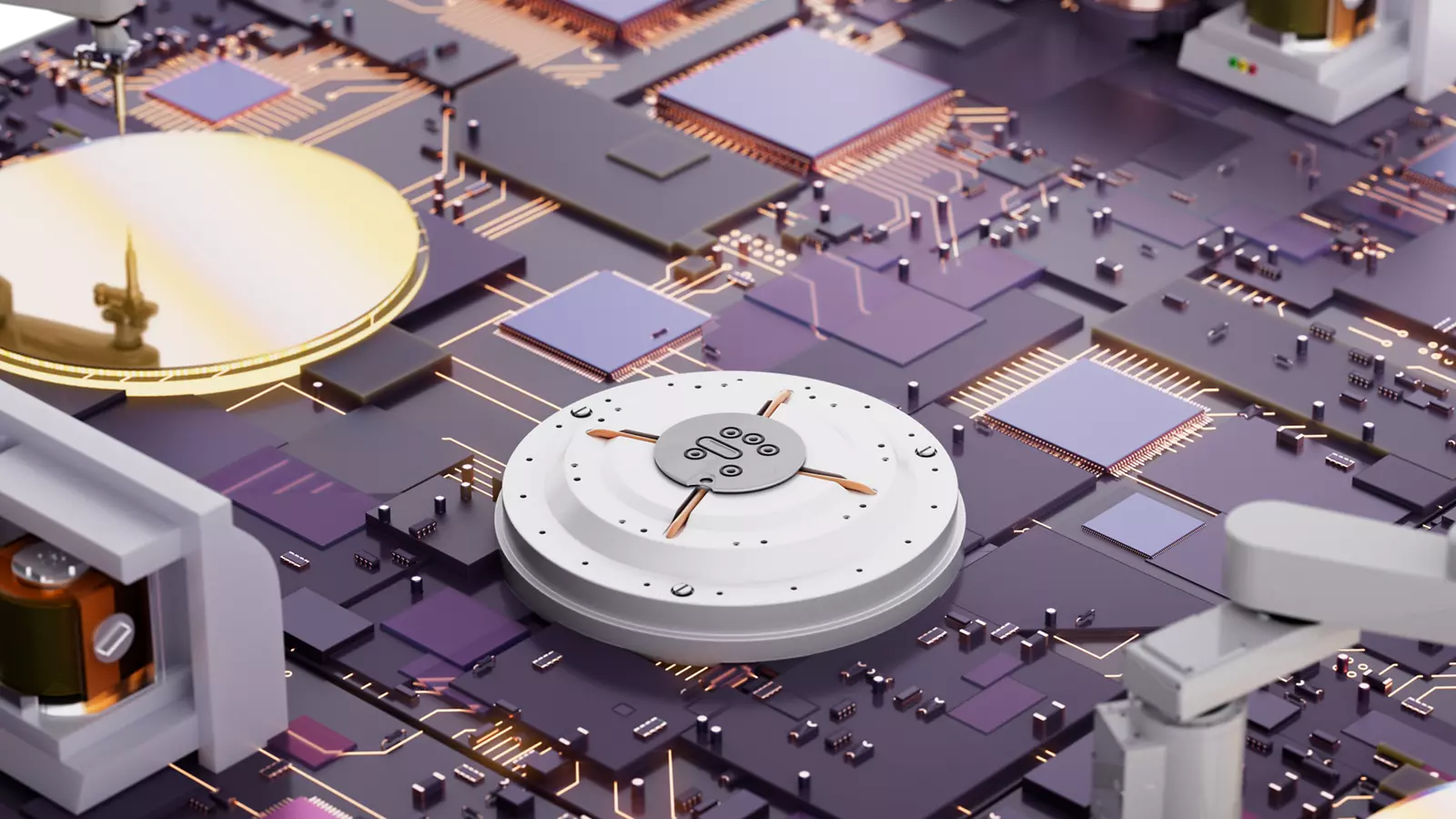

Air Compressors for the Electronics Industry

Did you know that one microscopic particle in your compressed air line can ruin an entire batch of expensive electronic components? In an industry that demands such precision, the quality of your high-purity compressed air is a direct link to your profitability and success.

Serving the electronics manufacturers across Yorkshire and the East Midlands, Search Air provides specialist Class 0 compressed air solutions from our depots in Leeds, Sheffield, and Nottingham. Our goal is straightforward: to help you reduce operating costs, ensure total compliance, and eliminate the risk of downtime caused by contamination.

The High Cost of Contamination in Electronics Manufacturing

In electronics manufacturing, you’re working at a scale where even the slightest impurity can cause catastrophic failure. Compressed air that isn’t 100% clean, dry, and oil-free poses a significant threat to your process.

The risks of contaminated air in electronics applications include:

- Product Rejection: Oil aerosols can compromise solder joints, while moisture can cause PCB delamination.

- Short Circuits: Conductive particles from rust or dirt can instantly ruin sensitive microchips.

- Equipment Damage: Solid or liquid contaminants may clog or damage sensitive pneumatic components in high-speed automation equipment.

The only way to avoid this risk is to meet the most rigorous industry standard: ISO 8573-1 Class 0. This means 100% oil-free air, guaranteed at the source.

The Solution: Atlas Copco Class 0 Certified Oil-Free Air

The only way to guarantee you meet the Class 0 standard is by using an oil-free compressor. At Search Air, we are a Premier Distributor for Atlas Copco, the world leader in oil-free technology.

- Atlas Copco ZR/ZT Rotary Screw Compressors: The workhorse for demanding industrial air compressors for electronics industry applications. These units are built for 24/7 reliability and are fully Class 0 certified.

- Atlas Copco SF Scroll Compressors: Perfect for labs or smaller, point-of-use applications that require quiet, vibration-free operation.

Choosing between oil-free vs. oil-lubricated air compressors for electronics industry usage is a critical decision. For electronics, oil-free compressors is the only choice that completely removes the risk of a catastrophic oil carry-over event.

Essential Air Treatment: Air Dryers and Filters

While the compressor generates the air, air treatment ensures its purity. To protect sensitive electronics, you must aggressively control moisture and particulates.

- Air Dryers: Desiccant or refrigerant air dryers are essential to lower the pressure dew point, preventing moisture from condensing on circuit boards during production.

- Air Filters: High-efficiency air filters remove atmospheric dust and particulates down to the micron level, ensuring the air stream is sterile.

- Filtration Strategy: Implementing a multi-stage filtration system protects both your pneumatic tools and the final product.

On-Site Nitrogen Generation

Beyond standard compressed air, many electronics manufacturers require high-purity nitrogen for wave soldering and selective soldering processes. Instead of relying on bulk deliveries, Search Air can help you install on-site nitrogen generators. These systems utilise your existing compressed air supply to generate nitrogen on demand, significantly lowering costs and improving supply chain security.

Cut Your Energy Costs, Not Your Air Quality

A high-purity compressed air system is often one of the biggest energy consumers in a facility. The good news is that you can achieve pristine clean air without excessive running costs.

By utilising VSD, heat recovery, and always-on leak detection, facility owners can reduce the Total Cost of Ownership (TCO) while delivering the necessary Class 0 purity at a lower energy cost.

- Slash Energy Use with VSD: Variable Speed Drive (VSD) electric motors can reduce energy usage by 35% or more, since these compressors automatically adjust their speed based on real-time demand for compressed air in your facility.

- Find and Fix Costly Leaks: A single small leak can cost thousands of dollars a year in wasted energy. Our ultrasonic leak detection audits find every leak, and we back the service with a money-back guarantee if it doesn’t save you money.

- Recover Waste Heat: Up to 90% of the energy a compressor uses is lost as heat. We can install heat recovery systems that capture this energy to provide free hot water for your facility.

Your Partner for Uptime and PSSR 2000 Compliance

Partnering with William G. Search Ltd. provides more than just industrial equipment; it gives peace of mind and guaranteed uptime.

Frequently Asked Questions

Are air compressors safe for electronics?

Yes, provided the air is properly treated. Raw compressed air contains moisture and oil, which are harmful. Using Class 0 oil-free compressors and proper air treatment makes the air safe for sensitive components.

What kind of compressor is the most commonly used in industries?

Rotary screw compressors are the standard for industrial electronics manufacturing due to their efficiency and ability to run continuously.

How much electricity does it take to run an air compressor?

This depends on the motor size, but compressors are significant energy users. Utilising VSD technology can significantly lower the electricity required.

What is a compressor in electronics?

In the context of the electronics industry, a compressor is the heart of the pneumatic system, powering automation tools, pick-and-place machines, and providing the gas supply for nitrogen generation.

We also offer integrated air dryers and air filters, as well as routine air compressor air quality testing to ensure that you are meeting the requirements of ISO 8573-1 Class 0.

Call the Search Air team today to schedule a complimentary system audit or to request a custom quote. Our specialists are here to design and engineer a certified Class 0 compressed air solution that protects your electronics manufacturing operations and lowers your operating expenses.

Want to know more about our electronics service?

Contact us