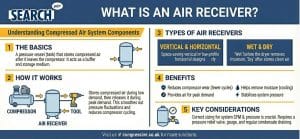

What is an Air Receiver?

An air receiver, also known as an air tank, stores compressed air under pressure.

It’s a crucial part of your system – not an optional extra.

For UK businesses, a correctly specified air receiver is key to efficiency, reliability, and legal compliance.

This bulletin will tell you what an air receiver does, how to size one, and what the law requires of you. By doing it right, you are on the surest way to lower energy costs, longer equipment life and safer operations.

Air Receiver Basics: More Than Just Storage

The air receiver acts as a buffer between the compressor and the wider system.

In most industrial settings, air demand rises and falls throughout the day. Without a receiver in place, the compressor has to keep stopping and starting every time the pressure changes. That’s energy and wear thrown away.

The receiver evens things out.

It supplies the burst of stored compressed air to absorb sudden peaks in demand. That lets the compressor operate in more efficient, longer cycles.

This simple action is the basis for all the receiver’s benefits. Take it out of the system, and everything starts to fluctuate. Energy costs go up, and reliability quickly drops.

Here’s Why Placement Matters: Wet vs. Dry Receivers

Where you place the receiver tank in relation to your air dryer is a strategic decision that affects air quality and system health.

- Wet Receiver: This is installed before the air dryer. It stores hot, saturated air directly from the compressor. As this air cools in the large tank, a significant amount of water vapour and oil condense and collect at the bottom. This makes the wet receiver a highly effective primary moisture separator, protecting your air dryer from being overloaded.

- Dry Receiver: This is installed after the air dryer and filters. It stores clean, dry air. Its primary purpose is to supply enormous, sudden demands for high-quality air without exceeding its rated capacity. This prevents moisture carry-over into your sensitive applications.

For most industrial systems, a correctly sized wet receiver is essential. Many applications with high-peak demands benefit from having both a wet and a dry compressed air storage tank.

An air receiver stores compressed air to stabilise pressure reduce energy use and protect compressor reliability

Technical Specifications & Sizing

An air receiver is a precisely designed pressure vessel, constructed to exact specifications. Here are some key specifications you should be aware of.

- Construction: Receivers are usually constructed of carbon steel. You can get galvanised or epoxy-lined interiors for enhanced corrosion resistance. They are available in vertical configurations to save floor space or horizontal models for sites with low headroom.

- Design Standards: New vessels supplied in the UK must be designed to standards like EN 13445 or BS EN 286. They must be manufactured with UKCA or CE marking and provided with a Declaration of Conformity.

- Pressure Ratings: Typical available pressure ratings are 11, 13 and 16 bar(g). High-pressure receivers are available for special process applications.

- Essential Components: All air receivers must be equipped with a pressure gauge for visual indication, a drain valve at the bottom of the receiver to facilitate the removal of condensate, and a safety relief valve to protect the receiver from over-pressurisation.

Search Air supplies Atlas Copco air receivers designed for seamless integration with connected technologies, including SMARTLINK remote monitoring, AIRnet piping, and AIRScan energy audits. This ensures complete system optimisation from a single source.

Let’s Look at How Sizing Works

Correctly sizing your air receiver is crucial.

An undersized tank forces the compressor to operate in a short-cycling mode. An oversized one is an unnecessary capital expense.

While a complete system audit provides the most accurate data, these rules of thumb from our Air Compressor Sizing Guide are a great starting point:

- For Load/Unload Compressors: Plan for 6–10 litres of receiver volume for every one cubic foot per minute (CFM) of compressor capacity.

- For Variable Speed Drive (VSD) Compressors: VSDs match output to demand, so you need less storage. A ratio of 2–4 litres per CFM is often sufficient.

For example, a 15 kW fixed-speed screw compressor delivering about 85 CFM would typically require a receiver of 500–1000 litres (85 CFM × 8,680 L, depending on load profile).

What is an Air Receiver

Benefits for Your Business

A correctly specified air receiver delivers direct financial and operational advantages.

- Improved Energy Efficiency: By reducing the frequency of motor starts, your receiver lowers energy consumption. The stable pressure it creates also allows your entire system to run at a lower setpoint. Each 1-bar drop in pressure can reduce energy costs by about 7%.

- Enhanced Performance and Quality: Steady air pressure keeps production quality high across every process – from paint finishing to food packaging. It keeps pneumatic tools delivering steady torque – while making sure control systems operate smoothly and reliably.

- Increased Compressor Reliability: Short-cycling is one of the main reasons motors, contactors, and valves wear out early. An air receiver dramatically reduces cycling frequency. This extends the life of your Air Compressors and reduces the risk of breakdown. When combined with remote monitoring tools like SMARTLINK and professional AIRScan energy audits, you get a fully optimised and predictive approach to system reliability.

Installation, Maintenance & Compliance in the UK

In the UK, the installation and inspection of most industrial air receivers are governed by law. It’s a responsibility you can’t ignore.

UK Law: PSSR 2000 Explained

If your compressed air system includes a pressure vessel where the pressure in bars multiplied by the volume in litres equals 250 or more, it falls under the Pressure Systems Safety Regulations 2000 (PSSR 2000).

The PSSR 2000 states that the ‘user’ or ‘owner’ of the system (usually the employer) has a legal duty to have a Written Scheme of Examination (WSE) in place.

A WSE is a formal document created by a “Competent Person” that details the inspection plan needed to keep your system safe. Operating a relevant system without a current WSE is illegal.

Installation and Maintenance Best Practices

- Installation: Set the receiver on a stable, level floor where it can be reached easily for checks and draining. Fit the safety valve so that any discharge goes to a safe spot, well clear of people and equipment. Your system should use properly sized AIRnet piping to minimise pressure drops.

- Air Receiver Maintenance: Regular maintenance is essential for safety and long service life.

- Daily: Check that the drain valve works properly and clears out any condensate.

- Quarterly: Test the function of the safety relief valve (following a safe, off-line procedure).

- Per WSE: Carry out the internal and external examinations as specified in your Written Scheme. The Competent Person defines inspection intervals, which typically range from 12 to 26 months, depending on the duty, condition, and risk assessment.

Condensate Management

The oily water that collects in a receiver is classified as controlled waste.

It cannot be discharged into a foul water drain legally. A Condensate Management system, utilising an oil-water separator, must be employed to remove the oil before disposal.

Expert Support for Your Compressed Air System

Your air receiver plays a vital role in the health, efficiency and compliance of your entire compressed air system. Get it right with expert guidance from sizing and installation to maintenance and statutory inspections.

As a Premier Distributor for Atlas Copco, Search Air provides nationwide installation and PSSR-compliant servicing for their systems, as well as for all other major compressor brands. Our engineers are experts in optimising complete systems to reduce operating costs and ensure safety.

Contact Search Air today for professional installation and PSSR-compliant service. Book your air receiver inspection or request a free airCHECK visual inspection of your compressed air system.