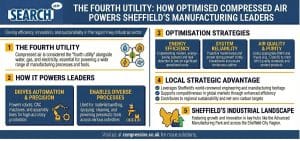

The Fourth Utility: How Optimised Compressed Air Powers Sheffield’s Manufacturing Leaders

The ‘Made in Sheffield’ mark is a global hallmark of quality. From a heritage in steel, we have transitioned into a new era of high-tech manufacturing. The ‘Made in Sheffield’ mark is on aerospace components, medical devices, and high-performance materials. Powering this innovation is a vital utility: compressed air.

This blog explores the role of compressed air in modern Sheffield manufacturing. For the city’s advanced industrial cluster, from aerospace hubs at the AMRC to specialist steel plants, optimised compressed air acts as the ‘fourth utility.’ It is generated on-site, which allows direct control over air quality, cost, and system reliability.

The Critical Role of Compressed Air Across Sheffield’s Industries

The specific demands for compressed air in Sheffield’s key sectors highlight the increasing sophistication of local manufacturing.

Advanced Manufacturing & Aerospace

Precision and quality are non-negotiable in this sector. Compressed air is essential for production.

- Automation & Robotics: It actuates robots for welding, gripping, and assembly operations.

- Pneumatic Tooling: It powers tools that have an excellent power-to-weight ratio, resulting in minimal operator fatigue.

- Material Finishing: It provides perfect surface prep and coating adhesion for a flawless finish.

Speciality Steel & Metallurgy

The city’s transformed steel industry requires powerful, reliable energy sources.

- Process Control: Used in pneumatic conveying systems to safely transport raw materials, it also powers industrial grinders and other heavy-duty equipment.

- Harsh Environments: Actuate large pneumatic cylinders that open furnace doors and control silo gates, requiring robust systems built for continuous use.

Medical Technology & Pharmaceuticals

Sheffield’s medical technology cluster operates under the industry’s most stringent standards. Here, air quality has a direct impact on patient safety.

- Sterile Applications: 100% oil-free compressed air is necessary for ISO 8573-1 Class 0 to avoid contamination of medical devices, instruments, or pharmaceutical products with microscopic oil residues.

- Cleanroom Environments: Air free from oil is required for sterile cleaning, tablet coating, and maintaining the integrity of the cleanroom HVAC system.

Optimised compressed air acts as the fourth utility supporting efficiency quality and reliability in Sheffield manufacturing

The High Cost of Inefficiency

A poorly managed compressed air system wastes capital. Energy can account for up to 80% of a compressor’s total lifecycle cost. A significant portion of this energy is lost due to systemic inefficiencies.

- Air Leaks: A common source of waste, leaks can account for 20-30% of a compressor’s output. A single 3mm leak can cost over £2,000 per year in wasted electricity. A professional audit for Compressed Air Leak Detection in Sheffield provides a rapid return on investment.

- Artificial Demand: Many systems run at a higher pressure than needed. For every two psi increase in pressure, energy consumption rises by approximately 1%.

- Inappropriate Use: Using a 100 psi air line for simple cleaning or cooling is wasteful. A low-pressure blower can often perform the same task with significantly less energy.

Innovative Technology: The Solution for Modern Manufacturing

Industry 4.0 principles are transforming industrial air systems from simple machines into intelligent assets that boost reliability and cut costs.

- Energy-Efficient Compressors: Plant air demand fluctuates. Variable Speed Drive (VSD) Air Compressors match motor speed to air demand, significantly reducing energy use. A VSD installation at a Sheffield engineering firm reduced the compressor’s energy consumption by 40%. Atlas Copco’s GA VSD+ models are examples of this technology, delivering pressures up to 13 bar(g) with IE4 premium motors.

- Guaranteed Air Purity: For sensitive applications, a specific compressor model, such as Atlas Copco’s Class 0 oil-free ZR/ZT range, guarantees ISO 8573-1 certified purity.

- Remote Monitoring: Modern air compressor monitoring systems, such as Atlas Copco’s SMARTLINK, utilise IoT sensors to track performance. This data enables predictive maintenance, preventing costly downtime and equipment failures.

- Heat Recovery: Up to 94% of a compressor’s electrical energy converts to heat. Heat recovery systems capture this thermal energy. In one Sheffield aerospace facility, introducing a heat recovery module cut annual heating costs by 25%.

The Fourth Utility How Optimised Compressed Air Powers Sheffield’s Manufacturing Leaders

Ensuring Full Compliance

Operating a compressed air system requires adherence to strict UK regulations. A specialist partner ensures your facility remains compliant with all necessary standards, including:

- Pressure Systems Safety Regulations 2000 (PSSR 2000)

- HSE PUWER 1998

- ISO 8573-1 (Air Purity)

- BS EN 1012-1 & -2 (Compressor Safety)

- ISO 14001 (Environmental Management)

Your Local Partner for a Powerful, Productive Future

For Sheffield’s manufacturers, operational excellence is a prerequisite for success. An unoptimised system is a direct liability.

Search Air (part of William G. Search Ltd.) is a local expert in optimising this critical utility. With over 75 years of experience and a dedicated Sheffield service centre, we provide the most reliable Air Compressors Sheffield businesses can depend on, combining deep industry knowledge with world-class Atlas Copco technology.

Our credibility is built on tangible results; a recent leak audit identified £171,780 in annual energy savings for one local business. As an Employee Ownership Trust, our team is committed to the long-term success of our clients. Compressed air is the lifeblood of many manufacturing businesses in Sheffield, so why not make the first move towards reducing your costs by starting to understand where and how you can save?

Call Search Air’s Sheffield office today on 0114 244 6521 or use our online form to arrange a free airCHECK assessment.