Services

Compressed Air Leak Detection

Compressed air is a versatile utility in industrial operations.

Many businesses and industries could not function without a reliable compressed air supply from their air compressor. However, air leaks are a fact of life for compressed air systems.

Wasting up to 30% of energy or more, compressed air leakage is expensive; it increases your system’s wear and tear and energy costs. Compressed air leaks can be difficult to spot; they are often small and, of course, it is just air. Some businesses lose 30% and more of their energy to leaks.

What causes costly leaks in compressed air systems

As it is a system under pressure, the air constantly tries to find a way out, and leaks happen for many reasons.

Natural Wear and Tear

Natural wear and tear can result in leaks, especially on parts like equipment connections and valves.

Accidental damage

Most workplaces have their share of bumps and knocks. These can create obvious leaks but can also loosen joints and connections.

Poor fittings

Adaptations or even poor initial installation can leave joints and bends that are loose, allowing compressed air to seep out.

How Professional Ultrasonic Leak Detection Works

Many of these leaks are undetectable to humans because they are so small and outside the range of human perception. Sometimes, even larger leaks go unnoticed because the pipes are obscured or hidden.

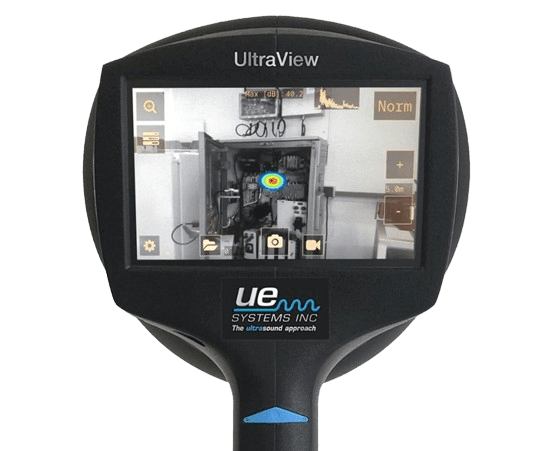

Professional ultrasonic leak detection overcomes this using a directional high-frequency, ultrasonic leak detector. Search Air engineers can use their microphones to hear, pinpoint air leaks, and even find those totally out of sight by following the tell-tale sound a compressed air leak makes.

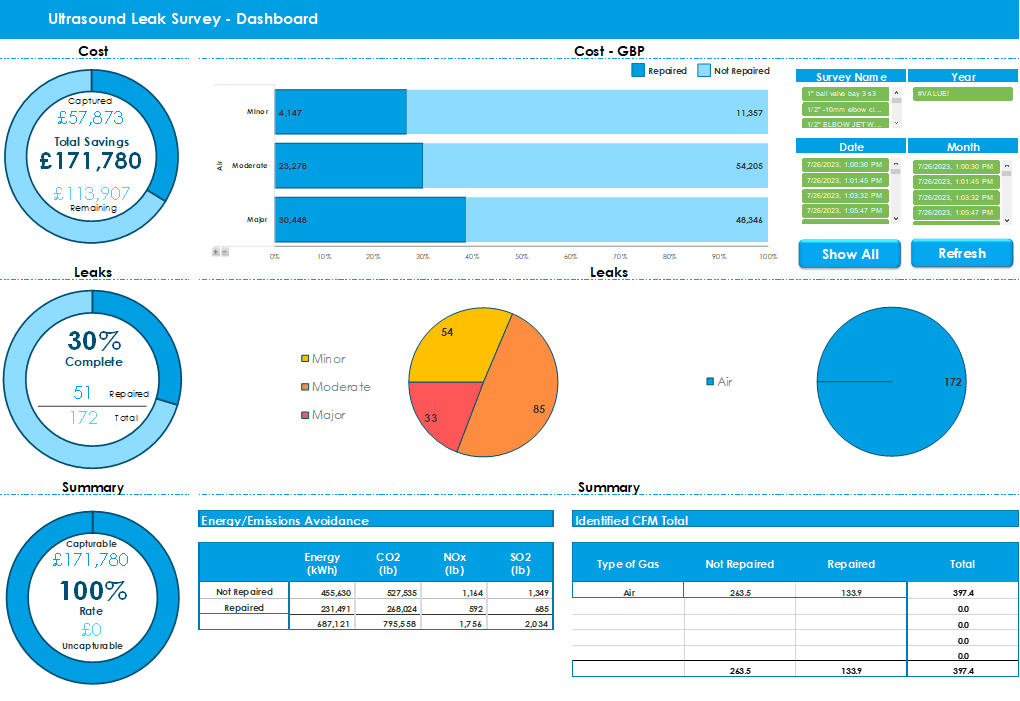

Each leak is identified, assessed, and logged. The result is a prioritised audit of leaks so you can address the costliest ones first, before fixing the smaller ones before they worsen. And because it is ultrasonic, it can all take place during your normal operations, so there is no disruption.

The benefits of professional air leak detection services

You might think that if you do not notice the air leak, it cannot be big enough to cause a problem. Sadly, leaks are a challenge for the industry. Those small leaks might not seem like much, but they quickly add up.

The result is that your system is put under more strain as it tries to compensate, but, at the same time, your productivity suffers because tools are underpowered or processes are not efficiently performed. In addition to the financial implications to income and expenditure, you may also find your equipment’s lifespan is drastically shortened.

Leak detection is a quick and easy way to make your system and operation more efficient and cost-effective.

Fix your air leakage today and request a leak survey

Arranging compressed air leak detection is simple. Contact Search Air, and we can arrange for one of our experienced engineers to visit your site. You might be surprised at how many leaks they find and how quickly it makes a positive difference to your bottom line.

Expanding on Technology and Monitoring

The Technology Behind Accurate Compressed Air Leak Detection

To effectively locate leaks, our engineers rely on advanced detection tools. While traditional methods exist, the use of ultrasound technology is key to high-accuracy compressed air leak detection. The turbulence created by escaping air generates a sound wave in the ultrasonic range, which is inaudible to the human ear. Our specialised acoustic camera and sensors convert this high-frequency sound into an audible signal and visual map, allowing us to precisely pinpoint the source of the leak—even in loud industrial environments. This ensures a detailed leak survey that no other method can match.

The Importance of Continuous Monitoring and Inspection

While a one-off leak survey provides immediate benefits, implementing a system of continuous monitoring and regular inspection is the best long-term strategy for energy conservation. Leaks in compressed air systems can develop rapidly. Proactive detection using reliable leak detectors prevents minor issues from escalating into major energy losses. Regular checks help us locate leaks early, mitigating the significant financial impact of wasted air. We can also discuss options for integrating permanent sensors into your compressed air system for automated monitoring.

Compressed Air Leak Detection Frequently Asked Questions

What is the price of ultrasonic leak detection and how much does a leak survey cost?

Our charges are based on the size of the system we need to assess. A thorough compressed air leak detection audit typically takes only a few hours and will quickly pay for itself.

Can I detect leaks myself?

It is possible to check for leaks in-house, even using old-fashioned techniques like soapy water. However, using experienced professionals like Search Air will result in quicker and more thorough leak detection.

Do I need to shut down my operation for leak detection?

No. Because we need the system operating to detect leaks, it is better if you continue working. Given that we use ultrasonic detectors, we can find leaks, no matter how noisy it is.

How to detect compressed air leaks?

The most effective way to detect compressed air leaks is through professional ultrasonic testing. This method uses acoustic technology to identify the high-frequency sound waves produced by escaping air, allowing engineers to locate leaks quickly and precisely, even those that are tiny or hidden.

Do you want to identify your air leaks and save money?

Contact us