Services

Air Compressors in Nottingham

Search Air is the premier partner for industrial compressed air systems in Nottinghamshire.

Based directly in Lenton, we provide rapid engineering support to businesses across Nottingham, from advanced manufacturing on the Blenheim Industrial Estate to food production in Colwick.

As an Atlas Copco Premier Distributor and the 2022 Distributor of the Year, we combine industry-leading technology with local expertise. Our team delivers energy-efficient installations, 24/7 emergency repairs, and full legislative compliance.

Contact our Nottingham team today:

- Call: 0115 986 1141

- Email: air@wgsearch.co.uk

- Visit: Unit 6, The Midway, Lenton, Nottingham, NG7 2TS

Why Partner With Search Air in Nottingham?

We keep your production running and your costs down.

- Reduce Energy Waste: Achieve typical VSD savings of 35–50%.

- Prevent Downtime: Local engineers and emergency hire cover ensure you keep working.

- Stay Compliant: We handle PSSR WSE, PUWER records, and condensate regulations.

- Improve Air Quality: We verify ISO 8573-1 air purity to your required class, up to Class 0.

How We Deliver Compressed Air Support

We do not just sell equipment; we optimise your entire system.

1. Site Walk & Risk Check

We inspect your system visually, checking the safety of your receiver, the condition of drains, and the status of your filters.

2. Measure & Monitor

Using AIRScan data logging, we measure your flow, pressure, and kW consumption. You get a clear baseline of your current efficiency.

3. Fix Quick Wins

We address immediate issues. This includes repairing air leaks, adjusting pressure setpoints to reduce strain, and replacing clogged filtration.

4. Plan Upgrades

Where necessary, we plan strategic upgrades, such as VSD compressors, heat recovery systems, or modular piping, to deliver long-term savings.

Local Service Capability in Nottingham

Downtime is the single biggest threat to profitability. You need a partner who can respond immediately.

Search Air operates a dedicated service centre in the heart of Nottingham.

- Rapid Response: With immediate access to the A52 and M1 (J24-J26), we typically achieve emergency attendance within 2 hours for Nottingham city centre and under 3 hours for surrounding areas like Beeston, Long Eaton, and West Bridgford, subject to site access and operational conditions.

- Strategic Coverage: Our engineers are permanently stationed to support key industrial hubs, including Blenheim Industrial Estate, Colwick Industrial Estate, and Nottingham Business Park.

- Emergency Hire Fleet: We maintain a local fleet of electric and diesel hire compressors. If a major failure occurs, we deploy a temporary unit immediately to keep your production line moving.

The Atlas Copco Technology Advantage

Energy consumption accounts for over 80% of a compressor’s lifecycle cost. We supply technology specifically engineered to reduce this expense.

GA VSD+ Series (Variable Speed Drive)

For Nottingham’s manufacturing base, the GA VSD+ offers a measurable reduction in energy consumption.

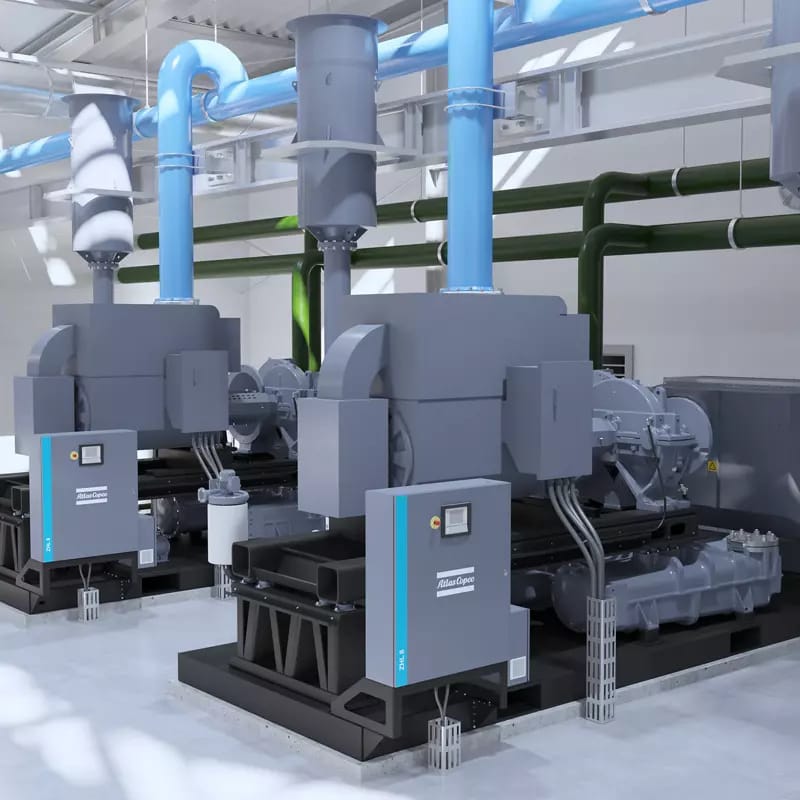

Z-Series (Oil-Free)

For critical applications, purity is non-negotiable. The Z-Series provides ISO 8573-1 Class 0 certified oil-free air, eliminating contamination risks at the source. This is the standard required for supporting Nottingham’s food and drink manufacturers and pharmaceutical sectors.

Energy & Cost Reduction Strategies

We find where your system is wasting energy, then fix it.

- Nottingham Business Decarbonisation Grant: Nottingham has set an ambitious target to become Carbon Neutral by 2028. To support this, local businesses may be eligible for grants of up to £10,000 to support energy efficiency upgrades. Our AIRScan audits provide the verified data required to support your application for this funding.

- VSD Savings: A Variable Speed Drive (VSD) compressor adjusts its motor speed to match real-time air demand. This eliminates wasteful idling and typically reduces energy consumption by 35–50% compared to fixed-speed units.

- Heat Recovery: Up to 94% of the electrical energy consumed by a compressor is converted into heat. Our recovery systems capture this thermal energy to generate hot water for industrial processes or space heating, reducing gas consumption.

- Leak Detection: Unmanaged leaks typically waste 20–30% of a system’s output. We offer compressed air leak detection in Nottingham using ultrasonic technology to pinpoint these losses. You get a prioritised action plan detailing exactly how much each leak costs you.

Compliance & Risk Management

Operating a compressed air system in the UK involves strict legal obligations. We help you stay compliant and audit-ready.

Pressure Systems Safety Regulations (PSSR 2000)

Any system where the pressure (bar) multiplied by the internal volume (litres) is greater than 250 bar-litres requires a Written Scheme of Examination (WSE). Operating without a valid WSE is illegal. We act as, or work alongside, an appointed Competent Person to draft the scheme and ensure your statutory inspections are compliant.

PUWER 1998

Your equipment must be “maintained in an efficient state.” Our rigorous maintenance records provide the necessary proof of compliance for safety inspectors.

Condensate Management (COSHH)

Compressor condensate is hazardous waste. It cannot be discharged into drains without treatment. We install and maintain oil-water separators to ensure you comply with environmental law.

Air Quality Standards (ISO 8573-1)

We verify your air quality against specific purity classes. This includes verification against the required ISO 8573-1 purity class for your application, up to and including Class 0 for pharmaceutical and life science environments, ensuring your system meets the stringent requirements for compressed air for Nottingham’s life sciences sector.

Technical Capability Snapshot

We provide a complete solution for any scale of industrial application.

| Feature | Specification |

| Compressor Types | Oil-injected rotary screw, oil-free (tooth/scroll/screw), reciprocating, centrifugal |

| Power Range | From 2 kW workshop units to 500 kW+ industrial systems |

| Pressure Range | Standard 7–13 bar(g); high-pressure boosters available |

| Dryer Types | Refrigerant (+3°C dew point), Desiccant (-40°C to -70°C dew point), Membrane |

| Monitoring | SMARTLINK remote monitoring, AIRScan data logging (flow/pressure/kW) |

| Hire Fleet | Electric portable (E-Air), diesel portable (XAS/XATS) |

Multi-Brand Service Capability

While we are the region’s premier Atlas Copco partner, our engineering expertise covers the entire market.

- OEM-Neutral Expertise: Our factory-trained engineers service and repair all major brands, including HPC Kaeser, CompAir, Ingersoll Rand, and Boge. We ensure your entire mixed fleet is maintained to the highest standard.

- Parts Supply: We utilise genuine or OEM-equivalent parts to ensure reliability and warranty compliance for every machine we service.

Your Local Partner in Nottingham

Search Air is an Employee Ownership Trust (EOT), meaning every member of our team is personally invested in your satisfaction. We are SafeContractor accredited and committed to delivering the highest standards of safety and quality.

Whether you need a new installation, a compliance audit, or urgent repair, our Nottingham team is ready to help.

Book your free airCHECK. Find compliance risks and energy waste before they cause downtime.